Har du brug for et svejset stik, så du nemt kan samle to forskellige stik i ét? Send en anmodning.

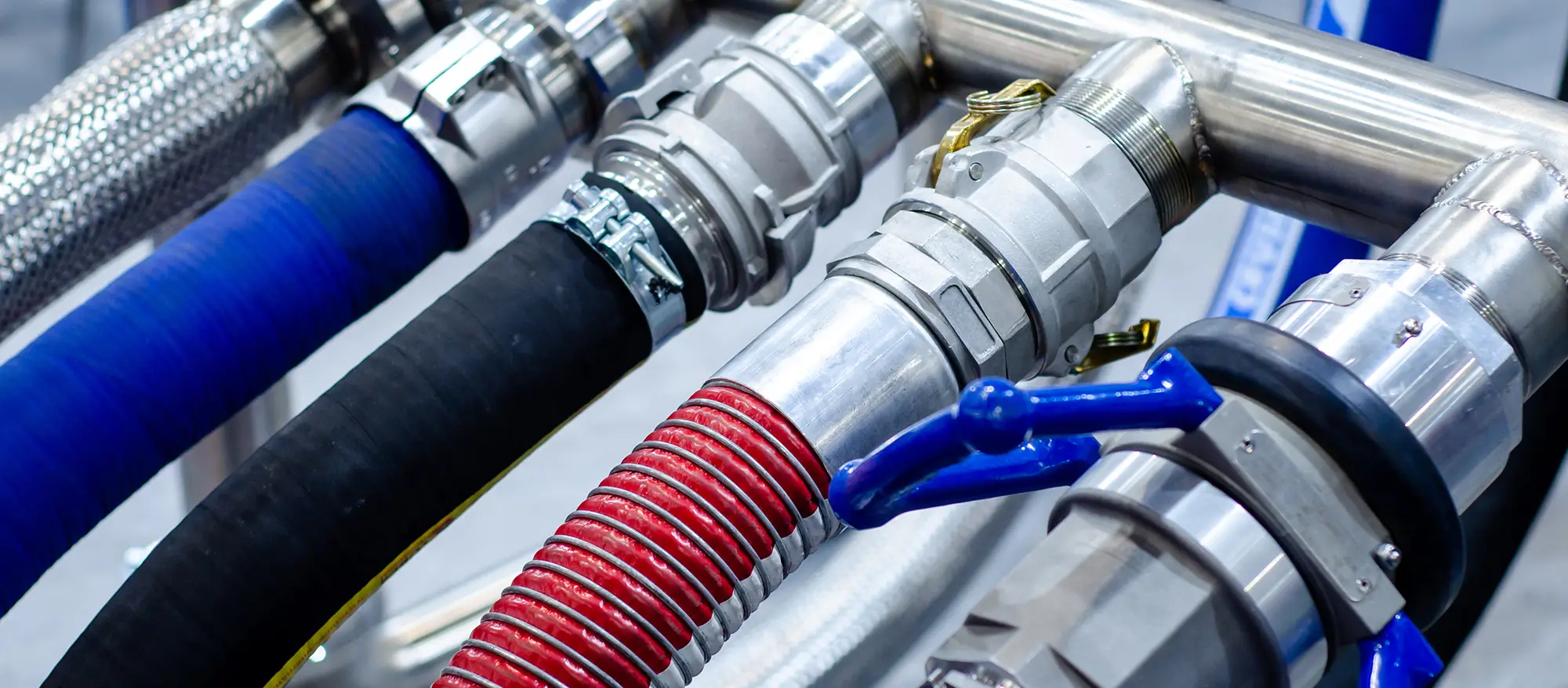

Composite hose PTFE (14 bar)

This Composite Hose PTFE (14 bar) is expertly designed for the safe and efficient transfer of aggressive chemicals and other challenging fluids. Featuring a PTFE (Polytetrafluoroethylene) lining, this hose offers exceptional chemical resistance, making it ideal for applications involving highly corrosive substances. Rated for 14 bar, it is the perfect choice for medium to high-pressure applications where reliability and safety are critical. Additionally, this hose can be customized with branding options such as different colors, your company logo, and other safety-enhancing information, allowing you to tailor it to your specific needs and enhance operational safety.

The Composite Hose PTFE is ideal for transferring aggressive chemicals, solvents, acids, and other corrosive fluids in industries such as chemical processing, pharmaceuticals, and industrial manufacturing, where chemical resistance and safety are essential.

Industries

Critical for industries including chemical processing, pharmaceuticals, petrochemicals, and industrial manufacturing, where the safe transfer of corrosive fluids is a key operational requirement.

Benefits

This hose provides outstanding chemical resistance thanks to its PTFE lining, combined with flexibility and long-lasting durability. The composite construction ensures compatibility with a wide range of chemicals while maintaining structural integrity under pressure. Rated for 14 bar, it is designed for medium to high-pressure applications, delivering reliable performance in even the most demanding environments. Additionally, customers can choose from a variety of end fittings, which can be securely attached to the hose through our professional service, ensuring a robust and leak-proof connection.

Operating Temperatures

Capable of withstanding a wide range of temperatures, making it versatile for various chemical transfer applications.

Pressure Classes

Rated for up to 14 bar, providing reliable performance in medium to high-pressure chemical transfer operations.

Certificates and Classifications

Complies with industry standards and certifications, ensuring safety and reliability in chemical transfer processes.

| Image | SKU | Size mm | Coil length | Max. work pressure bar | Minimale buig radius mm | Working pressure | Weight kg/mtr | Weld size mm | Ask for quote |

|---|---|---|---|---|---|---|---|---|---|

| SKU: COHMCR14-03806510 | Size mm: 1 1/2" | Coil length: 20 | Max. work pressure bar: 52.5 bar | Minimale buig radius mm: 140 mm | Working pressure: 10.5 bar | Weight kg/mtr: 1.7 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

| SKU: COHMCR14-05106510 | Size mm: 2 | Coil length: 20 | Max. work pressure bar: 52.5 bar | Minimale buig radius mm: 180 mm | Working pressure: 10.5 bar | Weight kg/mtr: 1.8 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

| SKU: COHMCR14-06306510 | Size mm: 2 1/2" | Coil length: 20 | Max. work pressure bar: 52.5 bar | Minimale buig radius mm: 203 mm | Working pressure: 10.5 bar | Weight kg/mtr: 2.9 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

| SKU: COHMCR14-07606510 | Size mm: 3 | Coil length: 20 | Max. work pressure bar: 70 bar | Minimale buig radius mm: 305 mm | Working pressure: 14 bar | Weight kg/mtr: 4.5 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

| SKU: COHMCR14-10206510 | Size mm: 4 | Coil length: 20 | Max. work pressure bar: 70 bar | Minimale buig radius mm: 406 mm | Working pressure: 14 bar | Weight kg/mtr: 7.9 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

| SKU: COHMCR14-15206510 | Size mm: 6 | Coil length: 20 | Max. work pressure bar: 70 bar | Minimale buig radius mm: 508 mm | Working pressure: 14 bar | Weight kg/mtr: 12.4 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

| SKU: COHMCR14-20406510 | Size mm: 8 | Coil length: 20 | Max. work pressure bar: 70 bar | Minimale buig radius mm: 737 mm | Working pressure: 14 bar | Weight kg/mtr: 21.8 | Weld size mm: 0.04 0.04 | Ask for quote: Ask for Quote |

Vil du vide mere?

Se de artikler, som vores slangeeksperter har skrevet om valg, brug og vedligeholdelse af forskellige slangetyper. Du får værdifuld information om forskellige emner, der påvirker valget af slanger.